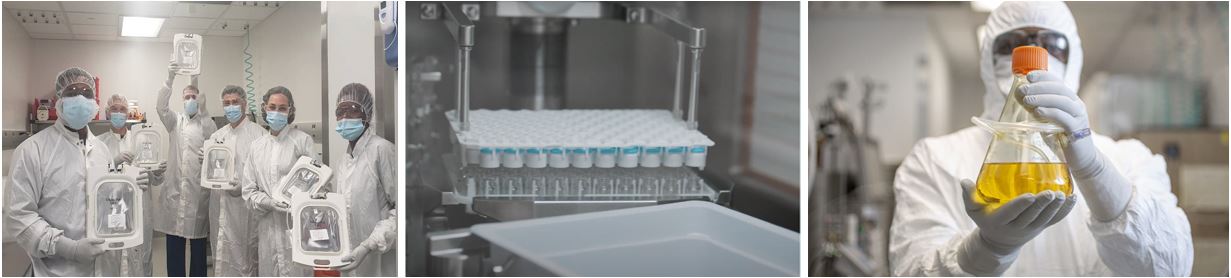

As of 2022, the Duke Human Vaccine Institute (DHVI) Bioprocess Technical Manufacturing Operations (BTMO) Unit houses two, purpose-built, cleanroom facilities totaling over 5000 square feet for the production of novel vaccine candidates to support proof of concept Phase I clinical trials under current Good Manufacturing Practices (cGMP).

Each facility houses state-of-the-art production equipment that can be easily reconfigured to support various vaccine production platforms, with the newest facility supporting simultaneous multi-product production.

Production is led by a dedicated cGMP BTMO team with a diverse background with experience ranging from small biotechnology companies, to large pharmaceutical enterprises. The cGMP BTMO team is comprised of a carefully selected group of engineers, scientists, and logistics personnel with experience in cell culture, fermentation, live virus operations, cell therapies, laboratory management, compliance, and quality assurance.

Our Mission

As a leader in vaccine research, at DHVI we believe that the creation of novel immunogens for use in early Phase I human clinical trials can be achieved at an accelerated rate and reduced cost without sacrificing the quality or safety of the final product. The DHVI GMP Program employs the use of a Quality Management System along with phase-appropriate regulations and guidance that govern early phase clinical manufacturing. We believe that ensuring product quality is a shared responsibility across departments, and the continuous dedication to improvement and maintenance of our quality system and operational capabilities ensures safe, consistent, and efficient manufacturing operations.

BTMO Production Capabilities

The modular capabilities of each manufacturing suite allow for a range of product platforms, including the production of immunogens via mRNA and Recombinant Protein, as well as fermentation and live virus capabilities. With the recent addition of Master and Working Cell bank production, Lipid Nanoparticle Encapsulation, and Fill-Finish operations, the DHVI GMP Product Development team is able to fully realize all stages of product production, from development, bulk drug substance manufacturing, drug product filling, and final product inspection and release for clinical use.

Master Cell Banking

As of 2020, the GMP Product Development team has brought Master Cell Bank production in-house, with the capability of producing up to 650 vial cGMP compliant cell banks. The addition of in-house cell banking allows for the preservation of a uniform cell population that is manufactured, stored, and controlled on-site to streamline future product production.

Working Cell Bank Production

650 Vial Working Cell Banks prepared from our in-house Master Cell Banks under current Good Manufacturing Practices provide a reliable production source critical for the development and manufacture of protein-based products.

Mammalian Cell Culture

The cGMP manufacturing suites house a wide variety of cell culture equipment that can be easily scaled to fit the production needs of each product campaign. The BTMO team is also supported by cell line and Process Development teams, striving to improve the efficiency and yield for our biopharmaceutical applications.

mRNA

The ability to manufacture mRNA via cell-free systems allows for reduced production timelines compared to recombinant protein production. To date the GMP Product Development team has manufactured a total of 5 mRNA products since 2021.

Live Virus

The modular capabilities of the cGMP suites also allow for the specialized handling and manufacture of attenuated (live) virus products by outfitting production suites and adhering to biosafety regulations to ensure proper controls during production.

Lipid Nanoparticle Encapsulation

Lipid Nanoparticles as delivery vessels for drug candidates have proven to be very promising and effective. In-house encapsulation of mRNA bulk drug substance to drug product allows for end-to-end processing and reduced timelines for final product release and supply to clinical trial sites.

Fill Finish

In house vial filling, inspection, and release have similarly accelerated the DHVI Product Development team's production timelines, providing a pathway for continuous processing from bulk drug substance, to drug product, to inspection and release, all overseen by our Quality Assurance and Regulatory teams.

Commitment to Quality

Within the DHVI Product Development Unit, we believe that Quality Assurance is a shared responsibility among all levels and departments within our organization. All aspects of operations supporting the manufacture and testing of cell banks, bulk drug substances, and drug products are overseen by a dedicated Quality Assurance team, collaborating closely with the BTMO and Analytical departments to ensure that the creation of novel immunogens for Phase I clinical trials can be achieved at an accelerated rate without sacrificing the quality and safety of the product. Learn more about our dedicated Quality team and our commitment to quality by clicking the link below to visit their page.